Battery energy storage systems (BESS) are fueling the global shift toward cleaner power, but as capacity expands, so does fire risk. Between 2018 and 2023, there were more than 60 large-scale battery storage fires worldwide, causing over $300 million in damage and months of operational downtime for affected facilities.

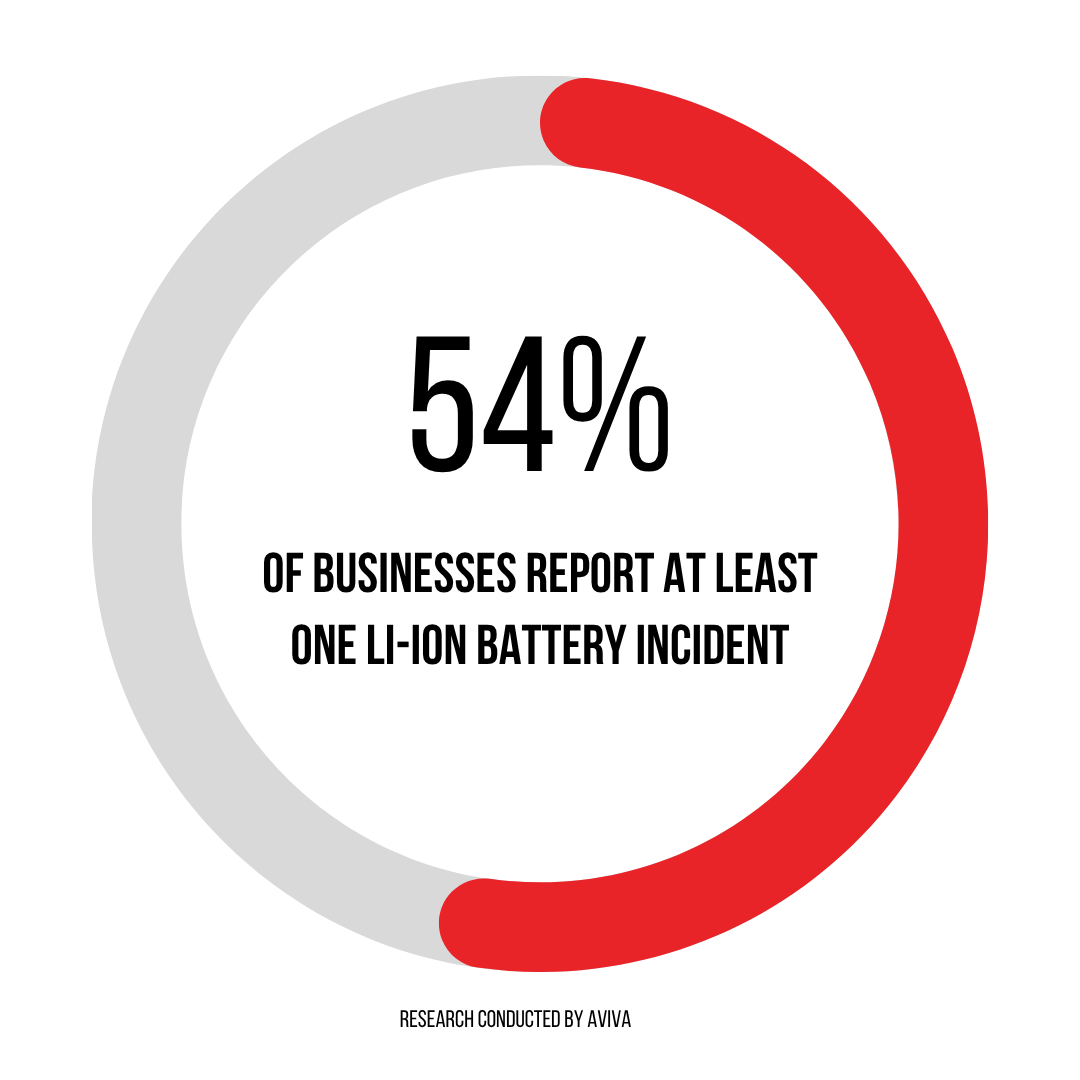

Even as safety standards improve, incidents continue to happen. A 2025 survey found that 54% of businesses had experienced at least one lithium-ion battery incident such as overheating, smoke, or explosion, and 19% reported actual fires.

For operators, a single event can result in lost equipment, regulatory fines, and serious reputational damage. That’s why reliable fire suppression systems, especially those designed for thermal runaway, are now seen as a core part of responsible energy management.

Understanding Thermal Runaway in Battery Storage

What Is Thermal Runaway?

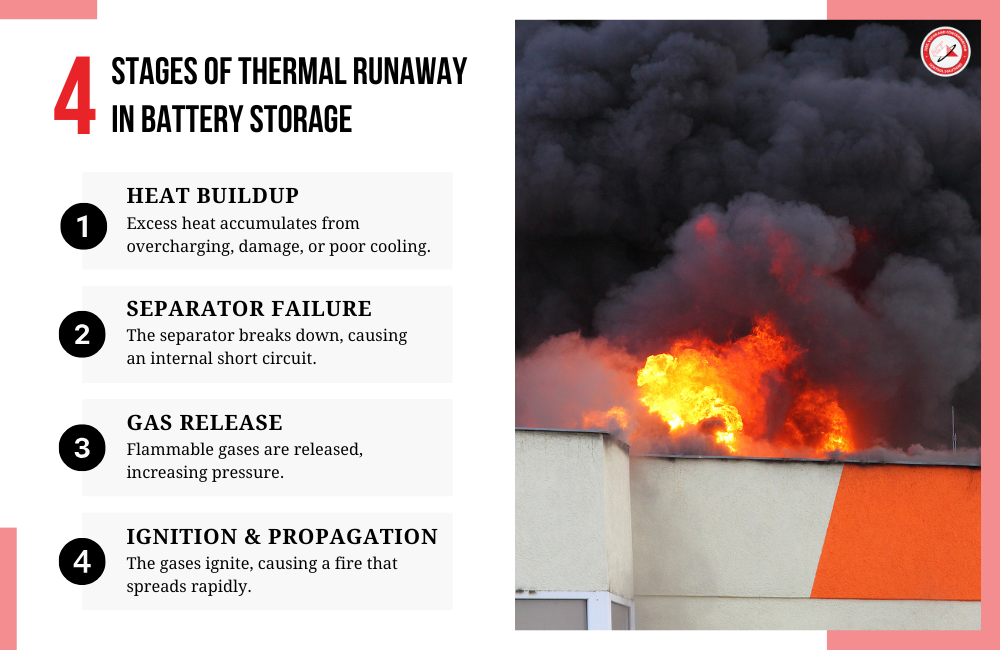

Thermal runaway is a self-accelerating process that occurs when a battery cell’s temperature rises faster than it can cool down. As the cell overheats, internal chemical reactions accelerate, creating even more heat. Eventually, the separator melts, releasing flammable gases and igniting nearby cells.

Common triggers include:

- Overcharging or faulty charging equipment

- Internal short circuits, mechanical damage, or physical damage

- Exposure to extreme temperatures

- Manufacturing defects or poor ventilation

Once a single cell ignites, the fire can spread rapidly through the entire battery pack.

Why Is Thermal Runaway Dangerous?

The biggest danger of thermal runaway lies in its speed and intensity. A single damaged cell can reach temperatures over 1,000°C, venting toxic gases such as hydrogen fluoride and carbon monoxide. Nearby cells can ignite in seconds, producing violent explosions and dense smoke.

Real-world incidents underscore the potential risk. Energy storage facilities in Arizona and South Korea have experienced major lithium-ion battery fires (electric vehicle and stationary battery fires) that required weeks to control and caused widespread damage. These events have led safety professionals to rethink fire suppression strategies for large-scale battery installations.

How Fire Suppression Systems Work in Battery Storage

Fire suppression systems in battery storage areas combine detection, control, and cooling mechanisms. Once heat or gas sensors detect abnormal conditions, suppression agents are discharged to cool affected cells, limit oxygen, and interrupt chemical reactions that sustain combustion.

The goal isn’t just to extinguish visible flames. It’s to stop the chain reaction that makes thermal runaway spread.

Types of Fire Suppression Agents

Water-Based Suppression Systems

Water remains one of the most accessible cooling agents. It can lower cell temperature and prevent heat from spreading. However, water-based systems can be less effective on electrical fires or where battery components react with water to release hydrogen. Specialized additives or misting systems are often used to improve performance and reduce electrical conductivity. Most facilities should integrate an automatic sprinkler system as part of their layered fire defense plan.

Clean Agent Systems

Clean agents like 3M™ Novec™ 1230 and other fluoroketone-based compounds suppress fires without leaving residue. They work by absorbing heat and interrupting combustion. While they are suitable for protecting electronic equipment and control rooms, they have limited cooling capacity for battery fires, making them better suited for enclosed spaces.

CO₂ Suppression Systems

Carbon dioxide reduces oxygen concentration around a fire to suffocate it. CO₂ systems work well in closed spaces but have limitations in battery storage environments due to re-ignition risk once the gas dissipates. Additionally, high CO₂ levels can pose safety risks to personnel.

Encapsulator Agents (EA)

Encapsulator Agents represent an innovative approach to battery fire suppression. F-500 Encapsulator Agent, developed by Hazard Control Technologies, works by encapsulating fuel, absorbing thermal energy, and interrupting the free radical chain reaction to successfully extinguish Battery Energy Storage System (BESS) fires and prevent re-ignition.

Its unique molecular structure attracts both water and hydrocarbons, creating micelles that trap and isolate fuels. This reaction rapidly cools burning materials and disrupts free-radical activity (the same chemical chain reaction that makes lithium-ion fires spread).

Because F-500 EA is fluorine-free, non-corrosive, and biodegradable, it offers a safe and sustainable alternative. NFPA 18A-compliant Encapsulator Agents provide both explosion protection and heat control, giving facilities a reliable path toward safer suppression.

Why Battery Storage Requires Specialized Fire Protection

Unique Risks of Battery Storage Facilities

Battery energy storage systems (BESS) pack a large amount of electrical energy into compact enclosures. Their high energy density, sealed casings, and interlinked modules make fires hard to reach and even harder to cool. Once a fire starts inside a module, it can spread between cells through radiant heat or vented gases.

In an audit of battery storage sites, 26% had fire suppression defects, and 18% had faulty thermal management systems. For operators managing hundreds of battery modules, even minor oversights can create major vulnerabilities.

These conditions require specialized fire suppression agents that can penetrate modules, cool internal components, and control vapor releases.

Environmental and Safety Concerns

Improper suppression can worsen the situation. Some extinguishing agents release toxic byproducts when interacting with battery materials. Others cause runoff contamination or leave residues that complicate cleanup.

Hazard Control Technologies addresses these risks with fluorine-free encapsulator agents and engineered proportioning systems that protect both personnel and the environment.

Fire Protection Solutions for Different Battery Types

Lithium-Ion Batteries

Lithium-ion batteries are widely used for energy storage but are also the most prone to thermal runaway. Their flammable electrolytes and tight energy density make them highly reactive under heat or damage.

F-500 Encapsulator Agent provides three primary benefits for lithium-ion incidents:

- Encapsulation: Encapsulates both polar and non-polar fuels, delivering long-term and stable burn-back resistance. Unlike foam, F-500 EA® can mitigate three-dimensional flowing fuel fires.

- Rapid Heat Reduction: F-500 EA® molecules form an outer layer on each water droplet, driving heat internally where spherical micelles absorb thermal energy. This ensures rapid cooling and reduces re-ignition risks in hazardous environments.

- Free Radical Interruption: Reduces the concentration of harmful hydrocarbons in smoke and soot by interrupting the free radical chain chemical reaction, ensuring cleaner, safer firefighting and fire protection.

This combination allows responders to manage fires faster and with less water, reducing damage and downtime.

Fire Detection Systems in Battery Storage

Importance of Early Detection

Early detection can make the difference between a manageable incident and a full-blown facility shutdown. Sensors that pick up temperature increases or gas venting allow suppression systems to activate before a fire spreads.

Hazard Control Technologies integrates detection systems directly with suppression agents for automatic activation. When detectors sense rising temperature or gas concentration, a 3% solution of F-500 EA is deployed to mitigate Battery Energy Storage System (BESS) hazards, halting escalation.

Types of Detection Systems

Battery storage facilities use a combination of:

- Heat detectors for temperature rise

- Smoke detectors for combustion particles

- Gas sensors for CO or hydrogen

- Thermal imaging for hotspot identification

When combined, these systems provide comprehensive protection, enabling rapid response before thermal runaway spreads.

Best Practices for Fire Protection in Battery Storage

Regular Maintenance and Inspections

Fire suppression and detection systems need routine testing to stay effective. Over time, nozzles can clog, sensors can drift, and batteries themselves can degrade.

Training and Safety Protocols

Personnel training is another key part of fire prevention. Teams should learn how to identify battery overheating, activate manual suppression systems, and follow emergency procedures. HCT provides on-site and online courses covering Encapsulator Agent use and hazard mitigation.

Fire Prevention Strategies

Many thermal runaway incidents can be avoided through proper facility design and safety measures, such as:

- Maintaining stable temperatures

- Installing ventilation systems to disperse heat and gas

- Using quality battery management systems (BMS)

- Separating battery modules to prevent chain reactions

HCT’s fire suppression and detection technologies integrate seamlessly into these preventive strategies, helping create safer energy storage environments and reducing explosion risks for operators and first responders.

How Hazard Control Technologies Protects Battery Storage

Hazard Control Technologies designs solutions that address the complex nature of battery fires. Our systems are built around the proven performance of F-500 Encapsulator Agent, a water additive that provides powerful cooling and vapor encapsulation.

In large-scale storage facilities, HCT systems can be configured with:

- Automatic detection and activation for rapid response

- Precision proportioning equipment like the Diamond Doser®

- Mobile or fixed suppression units for flexible deployment

- F-500 EA® Micelle Mist water-mist fire suppression systems

Through extensive testing and global installations, HCT continues to help industries, utilities, and emergency services reduce fire risk, protect personnel, and preserve the environment.