Warehouse Fire

Protection

How to Safeguard Your Warehouse Facility in the Age of Automation

Motivation for Change

Incorrect material handling and lifting techniques have been a leading cause of injuries within warehouses for decades

But today’s warehouse facilities face an additional and evolving hazard: the rapid adoption of electric material-handling fleets. Mega industrial warehouses, distribution centers, and logistics hubs are converting to lithium-ion battery-powered equipment to prioritize cleaner emissions, better safety, and streamlined workflows. These fleets often include:

- Forklifts

- Pallet Jacks

- Pallet Stackers

- Reach Trucks

- Order Pickers

- Tow Tractors

- Aerial Lifts

- Autonomous Mobile Robots (AMR)

Electric-powered material handling systems can contribute to a safer work environment and a more efficient workflow. However, it also changes the fire risk foundation that many warehouse fire protection system designs were originally based on.

According to the National Fire Protection Association (NFPA), U.S. fire departments respond to over 1,500 warehouse structure fires per year, resulting in hundreds of millions of dollars in property damage. These incidents often occur in large storage facilities exceeding hundreds of thousands of square feet, where fire behavior can expand quickly before a fire suppression system activates.

As warehouse fleets electrify, it has never been more important to keep safety measures and fire prevention strategies top of mind as we plug into a future driven by innovation.

Detection Challenges

The ability to detect toxic and explosive off-gases during the early stages of a lithium-ion battery fire is crucial for extinguishment

Lithium-ion battery modules commonly used in warehouses carry 15 kWh to 24 kWh of stored energy. If thermal runaway occurs, flame spread can move horizontally across racked inventory, conveyor lines, or neighboring equipment within seconds.

Although warehouse managers cannot control the volatile nature of a lithium-ion battery fire, they can control the early detection and fire protection systems that provide your team with the best chance of minimizing property and water damage, loss, and downtime.

Proximity

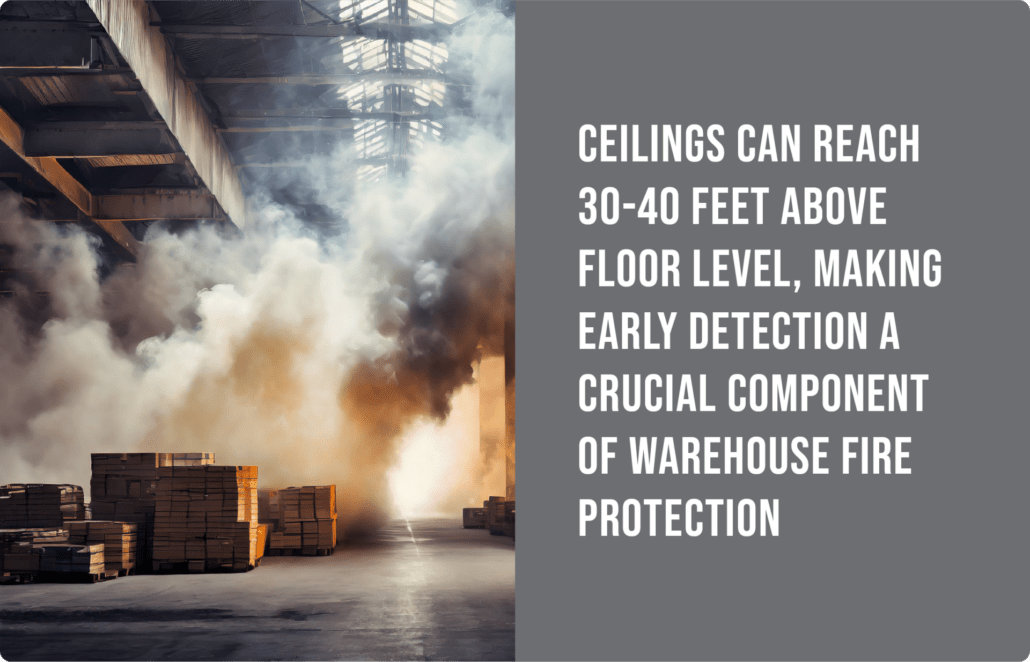

Lithium-ion battery failures release heavy vapor clouds long before flames appear. These vapors can increase intensity and ignition risk in concentrated charging zones. It’s not uncommon for the intensity of these vapors to outpace the detection capabilities of an Early Suppression Fast Response (ESFR) sprinkler system. These ESFR sprinklers, positioned 30–40 feet above floor level, may activate after the most dangerous stage of lithium-ion battery fires has already begun.

This time gap is one of the main contributors to rapid warehouse fire escalation.

Chemistry

Hydrogen is one of the first detectable gases in a battery failure, but it is only one part of the hazard. More than 100 flammable, explosive, and toxic gases may be released during thermal runaway, including gases that:

- Do not rise to ceiling-mounted smoke detectors

- Accumulate at breathing height

- Create flash fire and inhalation hazards

This is why many incidents originate in charging corridors and fleet parking areas – where electrical distribution, energy storage, and flammable materials intersect.

Engineering Success

Creating a balance between complete confinement and extreme elevation to protect our warehouses

As vertical rack storage continues to push the limitations of high-bay warehouses, typical ceiling heights have extended to 30-40 feet. These ceiling-level sprinklers don’t take parking and charging areas into account, leaving material handling equipment hazards unchecked. This has led some warehouse managers to invest in extravagant containment methods. Although these systems do offer benefits, they come with their fair share of fire protection challenges. Experiments conducted by UL involving Battery Energy Storage Systems (BESS) outline several key points.

Ventilating

The abrupt ventilation of an enclosed area, such as a BESS, may result in a deflagration or rapid transition to flashover.

Metering

The use of portable gas meters to evaluate interior conditions following a BESS fire can place personnel in a hazardous environment.

Monitoring

Built-in combustible gas and hydrogen detectors can be effective for indicating thermal runaway off-gassing, but they are not reliable for ongoing hazardous gas assessment.

Due to the life safety concerns presented by these structures, we believe a midpoint is necessary for effective fire protection. This could look like a canopy or in-rack sprinkler system equipped with ESFR sprinkler heads plus a vapor detection system fabricated over designated areas.

Best Practices

How we can improve the outcome of a contemporary warehouse fire by implementing a multifaceted approach

Modern warehouse fires unfold differently than the warehouse fires of previous decades. Historically, warehouse fires involved materials such as cardboard, lumber, textiles, and packaging materials, which burned more predictably and at lower heat release rates. Lithium-ion battery fires develop fast, release harmful gases before ignition, propagate horizontally, and pose inhalation hazards. Modern ESFR systems fashioned in high-ceiling warehouses can be slow to react in the event of a rapidly unfolding warehouse fire.

This is why localized suppression and targeted hazard control are necessary.

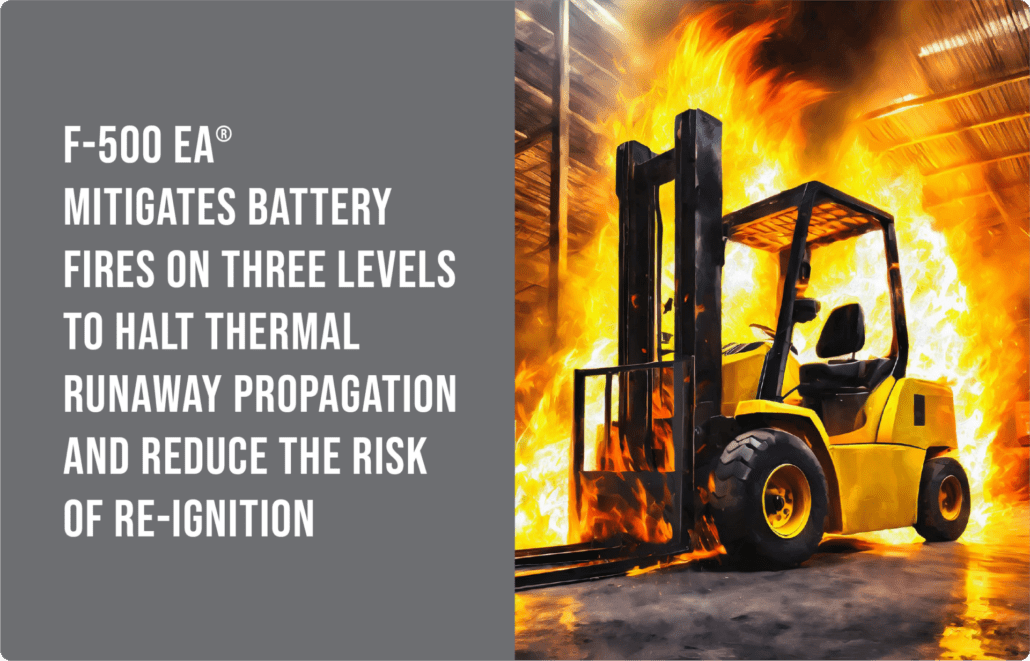

How F-500 EA® Works

F-500 EA® is an Encapsulator Agent that provides three layers of protection against lithium-ion hazards:

Flammability

F-500 EA® encapsulates flammable corrosive electrolytes and absorbs thermal energy up to 10x faster than water, slowing thermal runaway and stopping flame spread between battery cells.

Explosivity

F-500 EA® ceases the production of combustible and hazardous materials such as hydrogen, methane, and ethylene to prevent an explosion from occurring.

Toxicity

F-500 EA® reduces the concentration of toxic off-gases, including hydrogen fluoride, carbon monoxide, and carbon dioxide to protect human life.

No foam blanket. No film layer. No reliance on surface tension. It works at the molecular hazard level.

Prioritizing Fire Protection

Without adequate fire protection, your storage facility could potentially suffer a number of consequences in addition to a loss of life and property damage

1. Fines from a local governing body.

2. Higher insurance premiums, penalties, and refused coverage.

3. A significant loss of revenue during the period of re-building.

4. An irreparable reputation.

These outcomes underscore the importance of a fire protection system aligned to today’s hazards, not yesterday’s. Storage facilities must have a proactive approach to fire safety, involving inspections with fire departments and strict compliance with building codes.

The Diamond Doser®

The Diamond Doser® is a water-driven proportioner specifically designed to dose F-500 EA® concentrate directly into your ESFR fire sprinkler system‘s water stream. While incipient fires involving more organic materials used to take several minutes to become fully involved, today’s warehouse fires contain explosive, toxic, and flammable liquids that can cause blazes to spread rapidly. When every second counts, water supply is not enough.

Versatility

An engineered system designed to work hand in hand with NFPA (National Fire Protection Association) 18A recognized Encapsulator Technology, allowing for:

- Class A Fire Protection

- Class B Fire Protection (Polar/Non-polar/Three-dimensional)

- Energized Environment Fire Protection

- Class D Fire Protection

- Lithium Ion Battery Fire Protection

Continuity

An uninterrupted system as long as water and concentrate are available. If the tank is depleted, concentrate can flow continually from a separate drum or tote.

Consistency

A system that is always predictable, producing a solution with a consistent ratio that doesn’t fluctuate if additional sprinkler heads open at your facility.

Simplicity

Installation, operation, and maintenance are simple. The system is driven by water flow alone with no need for constant calibration or pressure balancing.

Efficiency

A flexible system with a wide pressure range of 2-12 bar or 2-16 bar that automatically corrects admixture accordingly. Testing is convenient, producing no agent waste.

Affordability

Instant savings on fire sprinkler installation as well as retaining thousands over time. This is done through effective fire suppression and economical annual NFPA-mandated testing that adheres to building fire codes.

Eco-friendly

Avoid unexpected system discharges, contamination, and disposal costs with a reliable system that utilizes fluorine free, biodegradable, and noncorrosive Encapsulator Technology.

Invest in HCT’s Fire Protection Systems

Prioritize warehouse fire safety with an innovative water-driven proportioner capable of pumping eco-friendly F-500 EA®directly into your water supply

Are you ready to invest in superior warehouse fire protection with F-500 EA®? We can help you implement a proactive approach that budgets for invaluable fire protection. Take the first step and contact our team of Encapsulator Technology Specialists to set up a free consultation.