Lithium Ion Battery Fire Extinguisher

The fluorine free solution delivering lithium ion battery fire protection to first responders and industry leaders

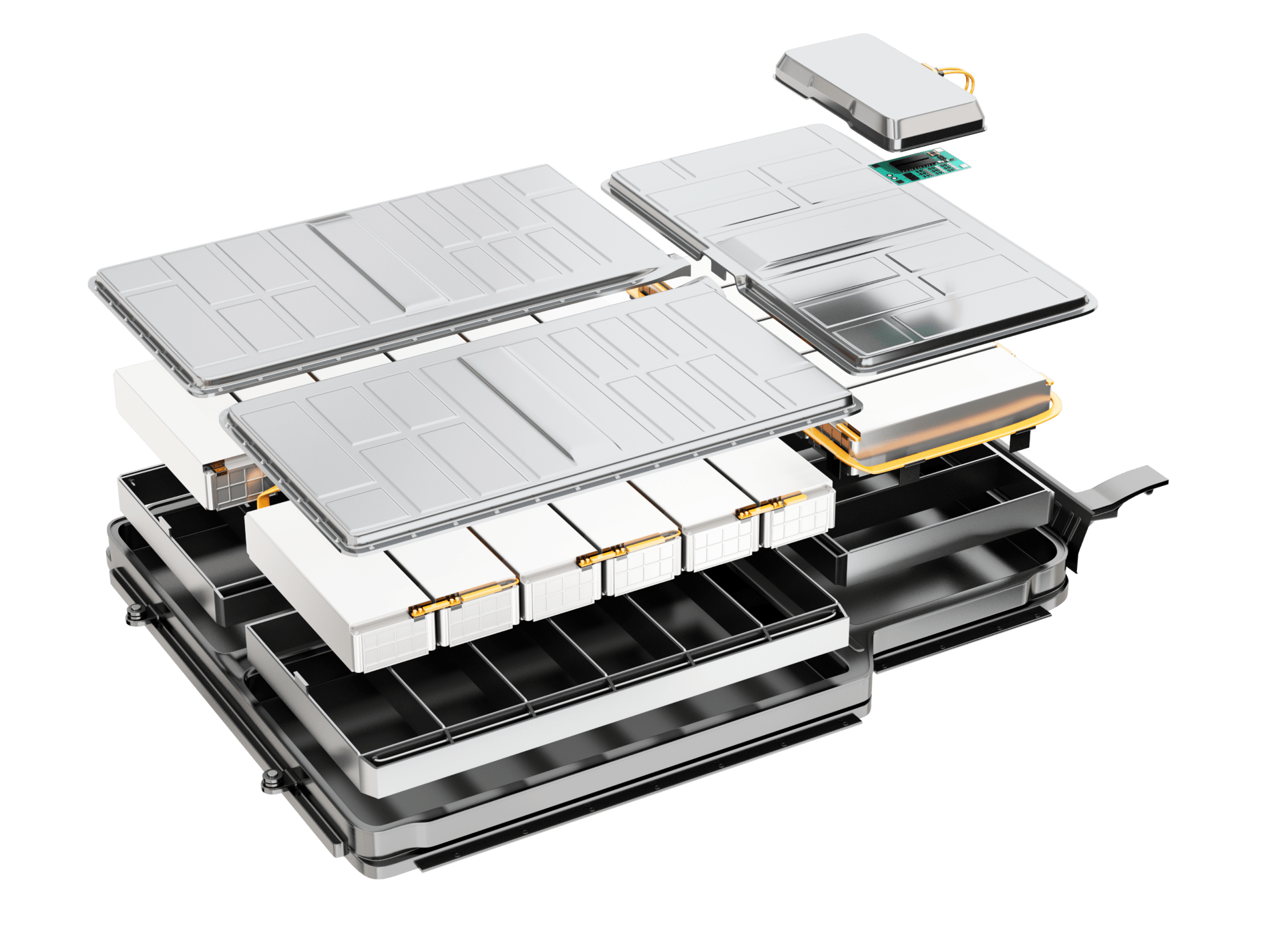

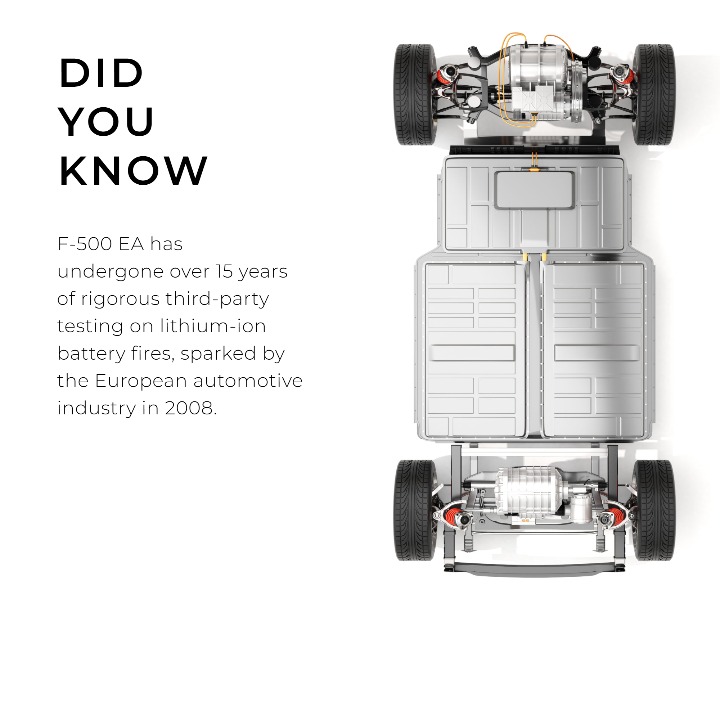

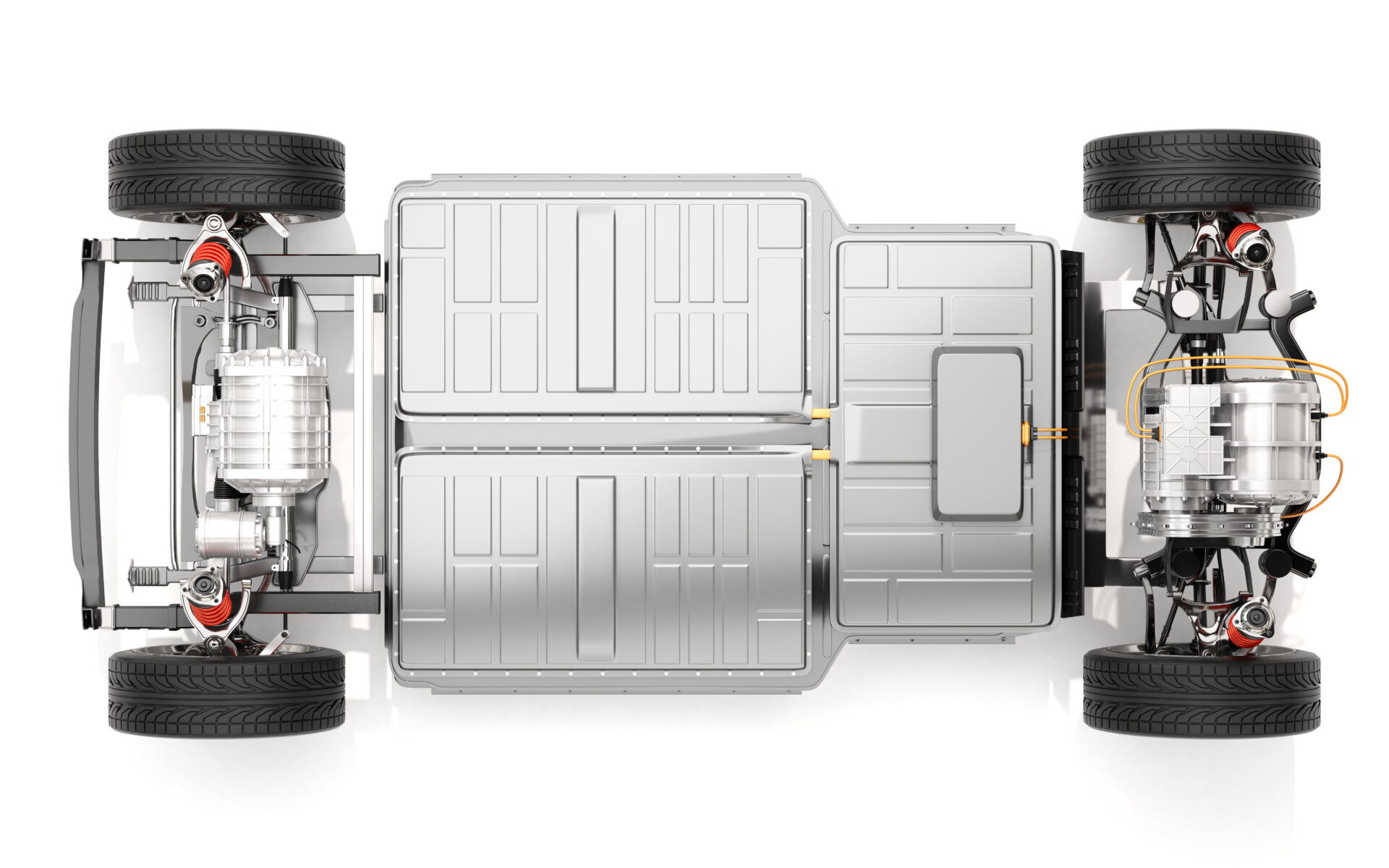

Lithium ion batteries are found in various contemporary devices, such as laptops and smartphones, as well as hybrid and electric vehicles due to their high energy density and reusability. However, they pose unique fire risks that differ from conventional blazes. A lithium ion battery fire, presenting Class A, Class B and Class C hazards, typically occurs due to thermal runaway. Lithium ion battery cells become overheated, which causes a chain reaction that can lead to a catastrophic fire or explosion without proper mitigation. F-500 EA is UL certified and recognized by NFPA for over fifteen years of scientific third-party testing on lithium ion battery fires across multiple continents.

F-500 EA mitigates lithium ion battery fires on three distinct levels

The hazards associated with lithium ion battery fires are varied and extend far beyond flammability. To offer effective lithium battery fire protection, it’s essential to understand the unique challenges posed by these fires.

MITIGATE

Flammability

An Encapsulator Agent is an efficient lithium ion battery fire extinguisher. F-500 EA encapsulates flammable corrosive electrolyte and rapidly absorbs thermal energy from high temperature flames. This successfully halts cell-to-cell ignition, also known as thermal runaway propagation. These features allow F-500 EA to provide long term stable burn back resistance and prevent reignition.

MITIGATE

Explosivity

F-500 EA ceases the production of explosive off-gases emitted by burning lithium ion batteries, such as Hydrogen (H2), Methane (CH4), and Ethylene (C2H4). This is especially important while extinguishing lithium ion battery fires within enclosed environments, such as apartments, data centers, aircraft cabins, energy storage systems, electric vehicles, and more.

MITIGATE

Toxicity

Encapsulator Agents reduce the concentration of toxic off-gases produced during a lithium ion battery fire, including Hydrogen Fluoride (HF), Carbon Monoxide (CO) and Carbon Dioxide (CO2). Many burning lithium ion batteries release both explosive and toxic off-gases, making it a necessity for firefighters to exercise caution and utilize personal protective equipment.

F-500 EA is tested, recognized and utilized by today’s trailblazers

Renowned organizations like Bosch, General Motors, Tesla, and more are benefiting from the peace of mind provided by the world’s most versatile lithium ion battery fire extinguisher: F-500 EA.