When you consider the potential dangers and challenges posed by Class D fires, it is important to understand the different types of fires in order to successfully achieve fire suppression. Class D fires are characterized by their involvement with combustible metals such as magnesium, sodium, aluminum, and titanium, and they are known for their resilience and ability to burn at exceptionally high temperatures. These types of fires generally require specialized extinguishing methods like a dry powder extinguisher due to the unique properties of the burning metals. In comparison, Class A, B, and C fires involve ordinary combustibles, flammable liquids and gases, and electrical equipment.

In industrial contexts, where combustible materials like shavings, powders, or solid metals are frequently stored, Class D fires present an even more significant risk. Because they can react violently with common extinguishing agents like water or carbon dioxide, it’s critical to approach these types of fires with an understanding of appropriate fire suppression techniques.

At Hazard Control Technologies, we offer extensive expertise in the field of fire suppression and fire protection. We are an ISO 9001 registered company that guarantees safety with each of our product offerings. When it comes to preventing fire hazards and ensuring fire protection, we are the number one source for providing the best fire suppression solutions.

Exploring Class D Fires

Class D fires, which are extremely dangerous and capable of causing significant damage, are fires that use combustible metals as their fuel source. But what exactly makes them unique and how do they differentiate from another type of fire? Let’s dive deeper to discover the specific characteristics and potential risks that are caused by class D fires.

Understanding Combustible Metals

In an environment where metals like magnesium, sodium, titanium, aluminum, etc. are stored, the risk of a Class D fire can be incredibly high. Magnesium burns with an intense, white flame, presenting not only a fire hazard but also a visual hazard to the firefighters trying to control it. Sodium, on the other hand, reacts with water as an explosion, which automatically takes out traditional fire suppression methods as a viable option. Also, the metal dust and shavings resulting from machining processes can elevate the fire risk. Even the smallest spark can lead to a rapid, explosive fire that spreads across an entire facility.

Risks and Challenges of Combustible Metal Fires

It is crucial to be aware of the risks involved with combustible and flammable metals, especially in places like industrial facilities or laboratory environments. Not only does a Class D fire build up quickly, but it also reaches incredibly high temperatures, capable of causing severe damage to structures and creating a serious threat to safety. The combustion process in a metal fire is also different than other types of fires. As metals oxidize rapidly, they release a large amount of heat and, in some cases, emit dangerous fumes that can present respiratory hazards.

Distinctive Characteristics and Challenges in Controlling Class D Fires

Compared to ordinary combustible materials or electrical fires, Class D fires emit extreme heat and, sometimes, toxic fumes. With the ability to emit such a high degree of heat, the inherent dangers require a specialized approach to be taken for containment and extinguishment.

Importance of Specialized Extinguishing Agents and Tools

HCT’s F-500 EA is the perfect solution to growing fire hazards. When it comes to extinguishing Class D fires, traditional agents like water or carbon dioxide are not only ineffective but also potentially dangerous. Traditional Class D extinguishers mitigate small-scale combustible metal fires by smothering them and restricting oxygen to prevent incipient Class D fires from growing any larger. F-500 Encapsulator Agent works on all four legs of the fire tetrahedron simultaneously. This process involves separating the fuel from oxygen on a molecular level to provide long-term and stable burn back resistance while rapidly absorbing thermal energy. F-500 EA’s high molecular weight provides the ability to interrupt the production of free radicals in smoke and soot. This allows F-500 EA to halt the chemical chain reaction and reduce the concentration of toxic fumes firefighters are exposed to during a Class D metal fire.

Aside from choosing the right extinguishing agent, it’s also important to guarantee the use of suitable equipment that can safely and effectively apply the agent from a safe distance, considering the extreme heat and potential damage of a Class D fire.

Differentiating Between Fire Classes

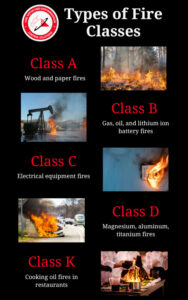

Understanding the differences between Class D and other classes of fires is important for responding to and managing the flames effectively. The use of extinguishing agents only suitable for Class A, B, or C fires, such as water or a CO2 extinguisher, can be dangerous when dealing with a Class D fire. The following is a breakdown of the different types of fires and what materials they involve:

- Class A fires: involve solid materials like wood and paper

- Class B fires (Lithium-ion battery fires): involve combustible liquids such as oil and gas

- Class C fires: electrical fires that involve energized electrical equipment

- Class D fires: consist of combustible metals like magnesium, aluminum, titanium, etc

- Class K fires: encountered in restaurant settings and involve cooking oils and vegetable oils

Solutions for Managing and Suppressing Class D Fires

Incorporating Cutting-Edge Equipment

As stated before, HCT’s F-500 EA fire extinguishers are the most effective in suppressing Class D fires.

In addition to utilizing appropriate extinguishing agents, employing specialized equipment plays a crucial role in managing Class D fires safely and effectively. Utilizing a Class D fire extinguisher often involves an extension applicator, which facilitates the use of the extinguishing agent from a safer distance, safeguarding the operator from the risks of extreme heat and potential flare-ups. The detailed engineering behind these fire suppression systems ensures precise, targeted application of the extinguishing agent, which is crucial in gaining control over the dangerous spread of a metal fire. When added to your water stream, Encapsulator Agents form a protective “skin” around plain water droplets. This allows for the extinguishment of Class D metal fires without an adverse reaction, flash, or explosion.

Enrichment Through Training and Consulting

Expertise in managing Class D fires is not just about having the right equipment but is also involved with comprehensive training and consulting. We encourage individuals to engage in hands-on training sessions that enhance their practical skills, while also getting involved with an expert who can provide strategies and plans for combating those intense fires in an industrial setting or laboratory environment. Enriching your knowledge and skills through expert guidance is important to make sure those attacking the fire are prepared and able to manage the challenges of Class D flames.

Mitigating Future Risks

Ensuring your team is confident in identifying, understanding, and effectively responding to a Class D fire not only safeguards personnel and property in the case of an incident but also facilitates a robust, long-term approach to risk mitigation and safety within your working environment. At Hazard Control Technologies, we are experts in this field. We have the skills and expertise to provide you with effective fire protection solutions, keeping in mind our top priority of safety.

Enhancing Safety with Hazard Control Technologies

In the act of addressing Class D fires, Hazard Control Technologies stands as a leader for our extensive expertise and innovative solutions. We have evolved from a manufacturer of a single fire suppression product to a global entity providing an array of fire suppression chemical agents, equipment, training, and consulting services. We promise products and services of the highest quality, all of which undergo rigorous testing and quality control processes.

Encapsulator Technology: A Breakthrough in Fire Management

Our F-500 Encapsulator Technology embodies an advanced approach to combatting Class D fires. This specialized agent directly addresses the unique challenges of a Class D fire with proven efficacy and minimal damage. Our technology not only suppresses fires effectively but also prevents the re-ignition of flames, providing a reliable and comprehensive solution.

Choose Hazard Control Technologies for your Fire Suppression Systems

At HCT, our expertise extends beyond providing solutions. We guarantee that your team is empowered with the knowledge and skills to effectively mitigate fires through our rigorous training programs and expert consulting solutions.

Choose Hazard Control Technologies as your preferred partner for extinguishing class D fires and contact us today to request a quote and step into the world of innovative fire protection and suppression solutions!

Resources:

- “ABCs of Fire Extinguishers.” The University of Texas at Austin. https://fireprevention.utexas.edu/firesafety/abcs-fire-extinguishers

- “Classes of Fires and Fire Extinguishers.” UCLA Health. https://www.uclahealth.org/safety/ambulatory-safety/ambulatory-fire-and-life-safety-program/classes-fires-fire-extinguishers

- Hazard Control Technologies. https://hct-world.com/