Understanding NFPA 409

When it comes to fire safety in aircraft hangars, few standards are as critical as NFPA 409. The National Fire Protection Association sets this standard, which “helps safeguard life and property through requirements for the proper construction and fire protection of aircraft hangars used for aircraft storage, maintenance, or related activities.” It is referenced by the International Building Code (IBC), the International Fire Code (IFC), and state and local ordinances. These facilities present unique challenges due to the activities conducted, the size of the aircraft, and the potential risks involved in operations.

Hangars are expansive spaces that house valuable and often flammable materials, including the aircraft themselves. The standard covers everything from the construction of hangars to the fire suppression systems that need to be in place. It ensures that these structures are safe and secure for those who work in them.

Compliance with NFPA 409 involves several key considerations. From the type of fire suppression systems installed to how hangars are constructed and maintained, every aspect plays a role in ensuring overall safety.

Key Requirements of NFPA 409

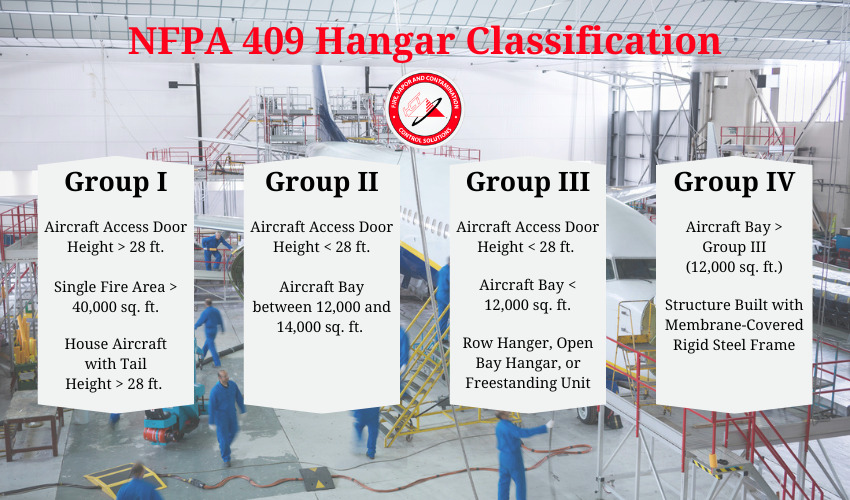

NFPA 409 defines hangar classification into four main groups, Group I, II, III, and IV, based on factors like the size of the hangar, the type of aircraft it houses, and the operations conducted within it. Each group has its unique fire protection requirements, tailored to address the specific risks associated with different hangar types.

Group I Hangars

Group I hangars are typically the largest and require comprehensive fire protection measures due to the significant amount of fuel and other flammable materials they store. They must have 1+ of these features:

- The aircraft access door height is more than 28 feet.

- A single fire area greater than 40,000 square feet.

- Can house aircraft with a tail height of more than 28 feet.

Group II Hangars

Group II hangars are smaller. They must have both of the following features:

- The aircraft access door height is less than 28 feet.

- Aircraft bay between 12,000 and 14,000 square feet.

Group III Hangars

Group III hangars must have a row hangar with multiple units, an open bay hangar that stores multiple aircraft, or a freestanding unit for one aircraft. They must have both of these features:

- Aircraft access door height of less than 28 feet.

- The aircraft bay is less than 12,000 square feet.

Group IV Hangars

Group IV hangars must have an aircraft bay larger than Group III and be a structure built with a membrane-covered rigid steel frame. biodegradable, making them a responsible fire protection solution for aviation leaders transitioning away from Milspec AFFF and AR-AFFF foams.

Recent revisions to NFPA 409 allow aircraft hangar owners to take control of their fire protection plans, opting for superior fire suppression solutions such as Encapsulator Agents when needed.

Beyond products, we offer consulting and training services to ensure that hangar operators understand fire safety protocols and the operation of fire suppression systems. This is an essential component of maintaining a safe and compliant environment.

Main Fire Protection Requirements

The NFPA 409 outlines several critical fire protection requirements that address the unique hazards of aircraft hangars.

Ignitable Liquid Drainage Floor Assembly

This requirement is for quickly and safely removing flammable liquids from hangar floors to reduce the risk of fire spread. The NFPA technical committee added this requirement in 2021 and it’s equivalent to traditional foam-based suppression systems.

Automatic Sprinkler System

NFPA 409 mandates specific types of sprinkler systems for each hangar group, ensuring that fire suppression capabilities are proportionate to the size of the hangar. It allows for automatic sprinkler systems in Group II aircraft hangars that don’t conduct hazardous operations.

Foam Fire Suppression Systems

Foam suppression systems can be effective against certain fire hazard within a hangar environment. The foam requirements were changed in the 2022 edition of NFPA 409, allowing hangar operators to utilize innovative fire suppression agents, such as Encapsulator Agents, for high hazard protection. Encapsulator Agent Suppression Systems quickly extinguish a variety of fires while minimizing damage to the aircraft and equipment.

These systems play important roles in aircraft hangar fire protection. They activate once they detect signs of a fire, significantly reducing the spread of the fire and minimizing any damage to the property.

Maintenance Requirements and Considerations

Regular maintenance and inspections of fire protection systems are emphasized in NFPA 409 to make sure they remain functional and effective at all times. This includes routine checks of sprinklers, foam systems, alarms, and other safety equipment. Understanding and implementing these key requirements is a proactive step towards the highest level of safety in aircraft hangar operations.

Fire Safety Solutions for Aircraft Hangars

The fire safety industry continuously evolves, with new trends and technologies emerging to better protect aircraft hangars against fire hazards. These advancements are driven by a commitment to enhance safety, efficiency, and compliance with standards like NFPA 409.

Performance-Based

Design Approach in Customized

Fire Protection Plans

NFPA 409 encourages a performance-based design approach for fire protection. This involves creating customized fire safety plans that cater to the needs of different aircraft hangars. Factors such as tail height, aircraft size, and specific hangar uses are considered to design a system that meets the exact needs of the facility.

For example, a hangar that houses larger aircraft with higher tail heights might require a different layout compared to a hangar used for smaller planes. Performance-based design allows for this level of customization and ensures that each hanger has the most effective solution.

Meeting NFPA 409 Standards

It’s important to understand how these standards can be met in practice, and this is where Hazard Control Technologies comes into play. We offer expertise and innovative products to ensure that aircraft hangars excel in adhering to NFPA 409 guidelines.

HCT’s approach involves a thorough analysis of each hangar’s specific requirements. Whether it’s a Group I hangar needing extensive fire protection or a smaller Group III facility, our team of experts designs and implements solutions that align with NFPA 409 specifications.

Benefits of Fire Suppression Solutions

Understanding that no two hangars are the same, HCT provides customized solutions for your facility. Our F-500 Encapsulator Agent quickly addresses fires and reduces the potential for re-ignition. Our agents address the specific risks associated with each hangar type and size, ensuring effective fire protection that meets NFPA standards.

Encapsulator Agents are now included in the FAA’s AC 150/5210-6E circular. F-500 EA® takes the guesswork out of any hangar emergency. Encapsulator Technology is safely mitigating a vast range of aviation hazards globally. In fact, Turkey is now utilizing F-500 EA® for lithium-ion battery hazard protection in 48 airports. Encapsulator Agents excel at both fire suppression and spill control while remaining fluorine-free, non-corrosive, and biodegradable, making them a responsible fire protection solution for aviation leaders transitioning away from Milspec AFFF and AR-AFFF foams.

Recent revisions to NFPA 409 allow aircraft hangar owners to take control of their fire protection plans, opting for superior fire suppression solutions such as Encapsulator Agents when needed.

Beyond products, we offer consulting and training services to ensure that hangar operators understand fire safety protocols and the operation of fire suppression systems. This is an essential component of maintaining a safe and compliant environment.

Preparing for the Future with Hazard Control Technologies

The fire safety landscape constantly evolves with changes in technology, aircraft design, and even regulatory standards like NFPA 409. At HCT, we recognize this change and are committed to preparing our suppression agents for future advancements. Our approach ensures that hangar operators are ready for emerging challenges and changes in fire safety protocols. We demonstrate this commitment through our F-500 Encapsulator Agent, a cutting-edge solution in fire suppression. The F-500 EA is highly effective, efficient, and environmentally friendly, aligning with the latest advancements in fire safety.

As regulations continue to evolve, partnering with HCT assures hangar owners that their facilities are prepared for the future of fire safety. We encourage aircraft hangar operators, fire protection engineers, and safety managers to work with our team to enhance the safety and compliance of existing and new hangar facilities. Reach out today to receive exceptional fire protection solutions.

Resources

- Hazard Control Technologies. https://hct-world.com/

- National Fire Protection Association. https://www.nfpa.org/en