Encapsulator Technology

Encapsulator Agents

NFPA 18A

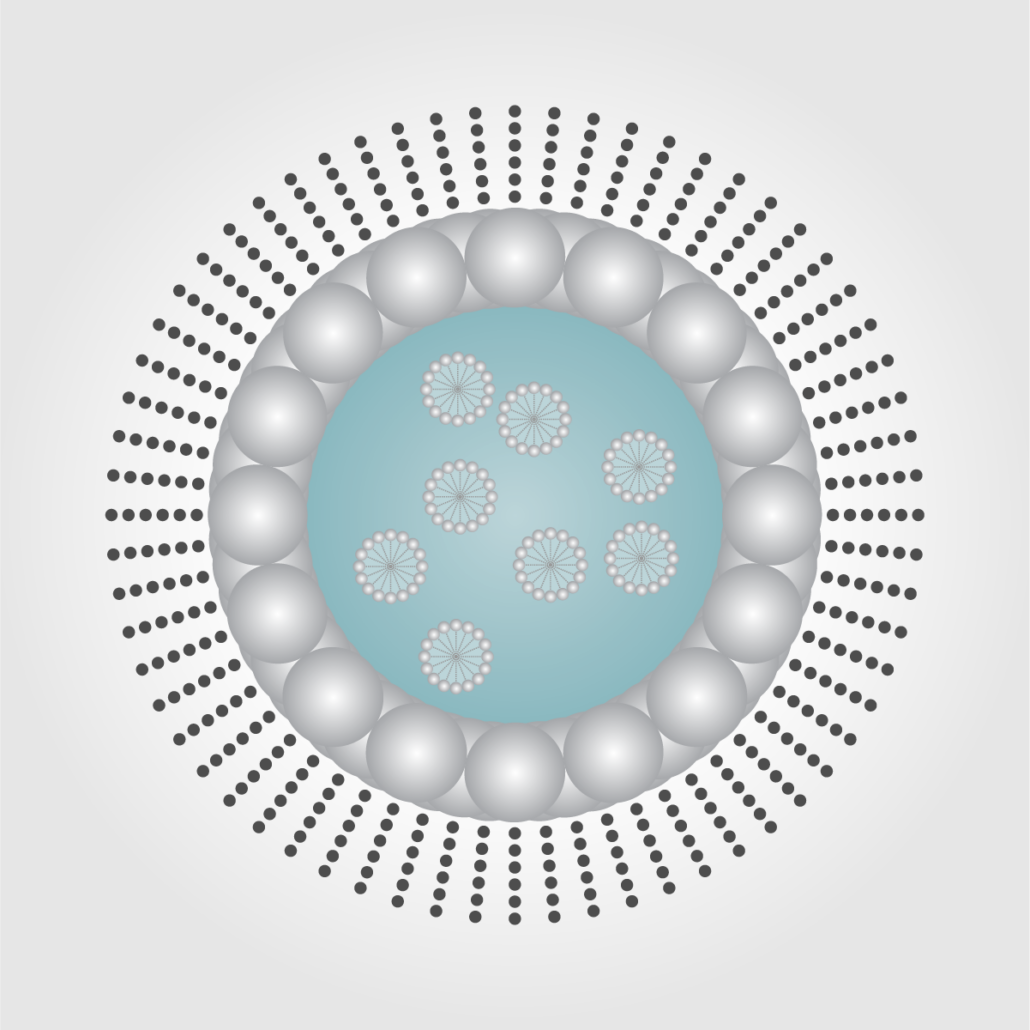

A type of water additive whose basic building blocks are spherical micelles capable of encapsulating carbon molecules as well as both polar and non-polar hydrocarbon vapor and liquid molecules, separating fuel from oxygen on a molecular level.

PROPERTIES

- Encapsulation YES

- Rapid Heat Reduction YES

- Free Radical Interruption YES

- Surface Tension Reduction YES

Wetting Agents

NFPA 18

A chemical that can be added to a liquid to reduce its surface tension and make it more effective in spreading over and penetrating surfaces.

PROPERTIES

- Encapsulation NO

- Rapid Heat Reduction NO

- Free Radical Interruption NO

- Surface Tension Reduction YES

Testing

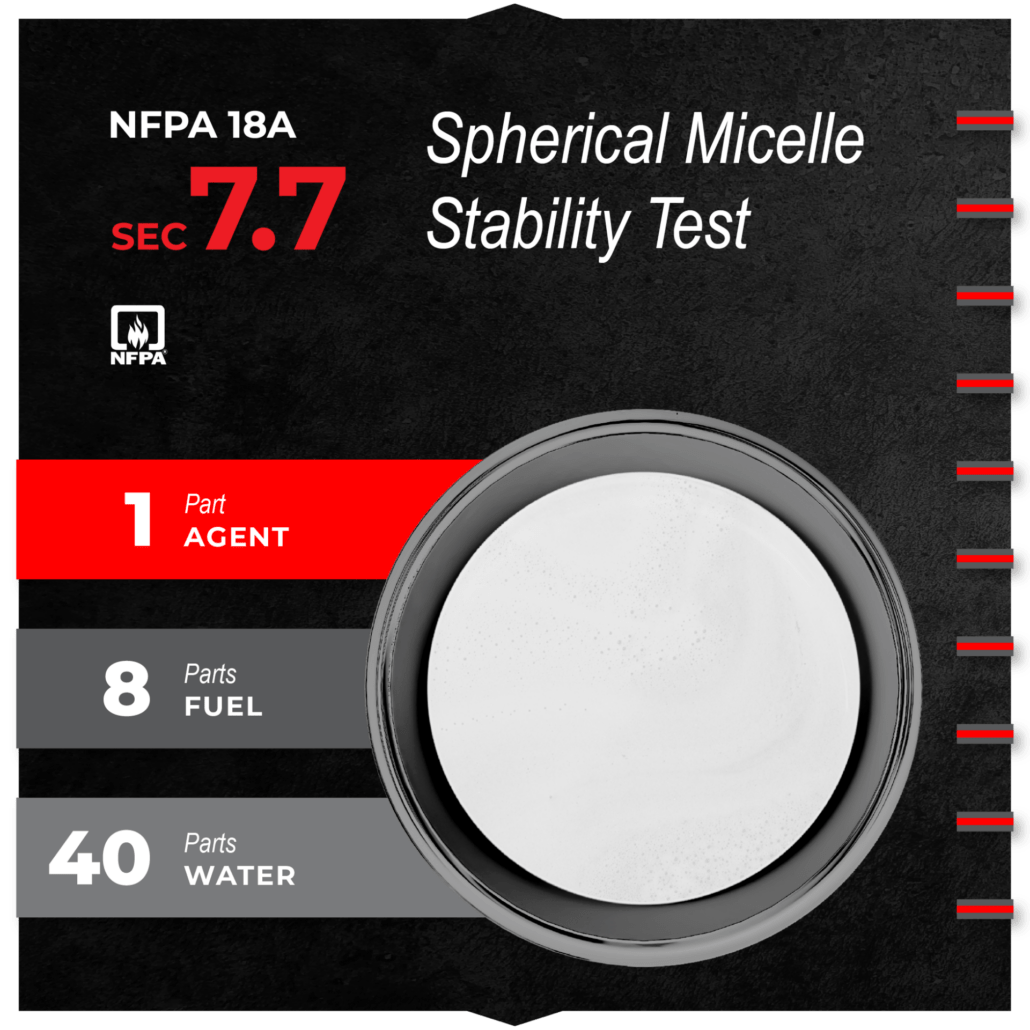

NFPA 18A Sec 7.7

SPHERICAL MICELLE STABILITY TEST

This section covers the test procedures to evaluate

the ability of a water additive solution to form and

maintain stable spherical micelles capable of

encapsulating combustible and flammable liquids

(polar and non-polar), rendering the flammable

liquids nonflammable, nonignitable and

nonexplosive and maintaining that encapsulation

in the presence of high heat over an extended

period of time.

Molecule

Polar Head

HYDROPHILIC

In Solution Outward Exiting Nozzle Inward

Non-polar Tail

HYDROPHOBIC

In Solution Inward Exiting Nozzle Outward

Features

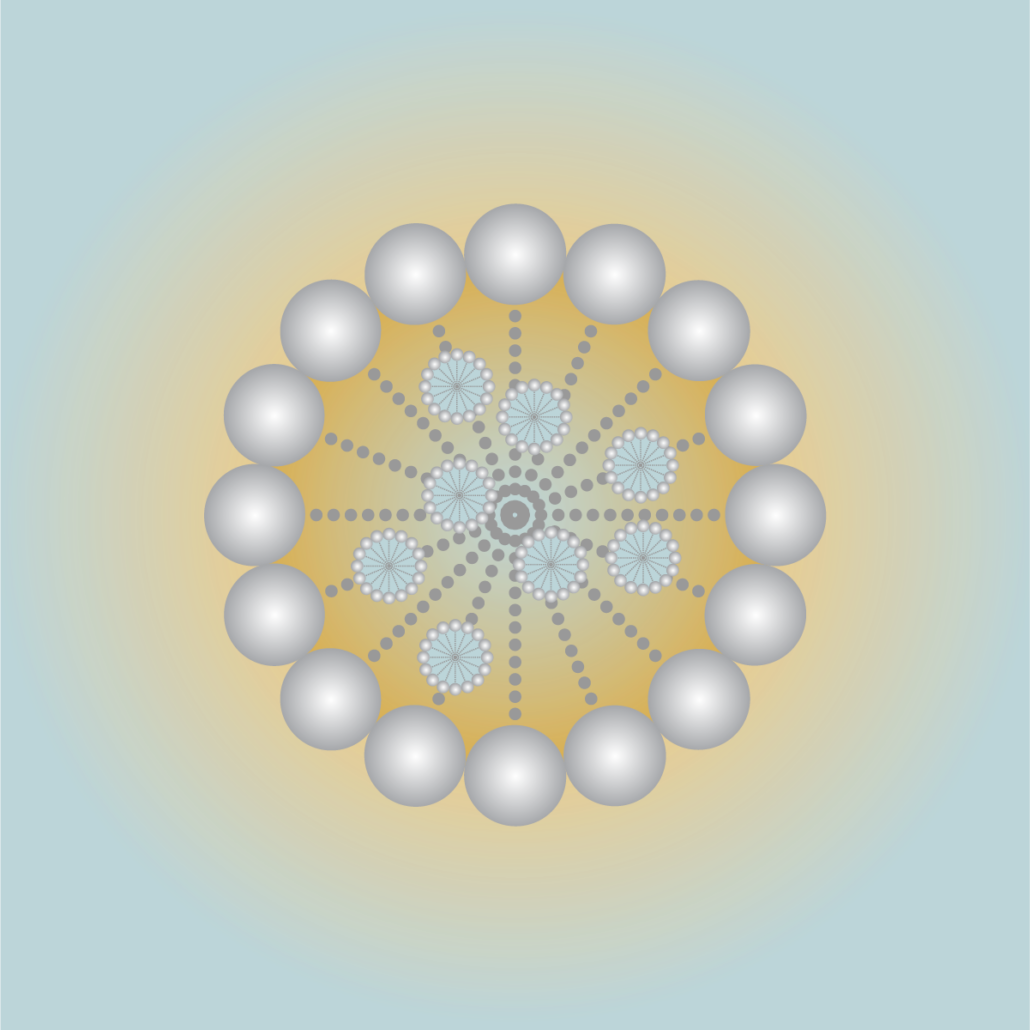

Encapsulation

BENEFITS

- Expanded Hazard Mitigation

- Elimination of Flammability

- Stable Long-term Burn Back Resistance

- Simplified Cleanup

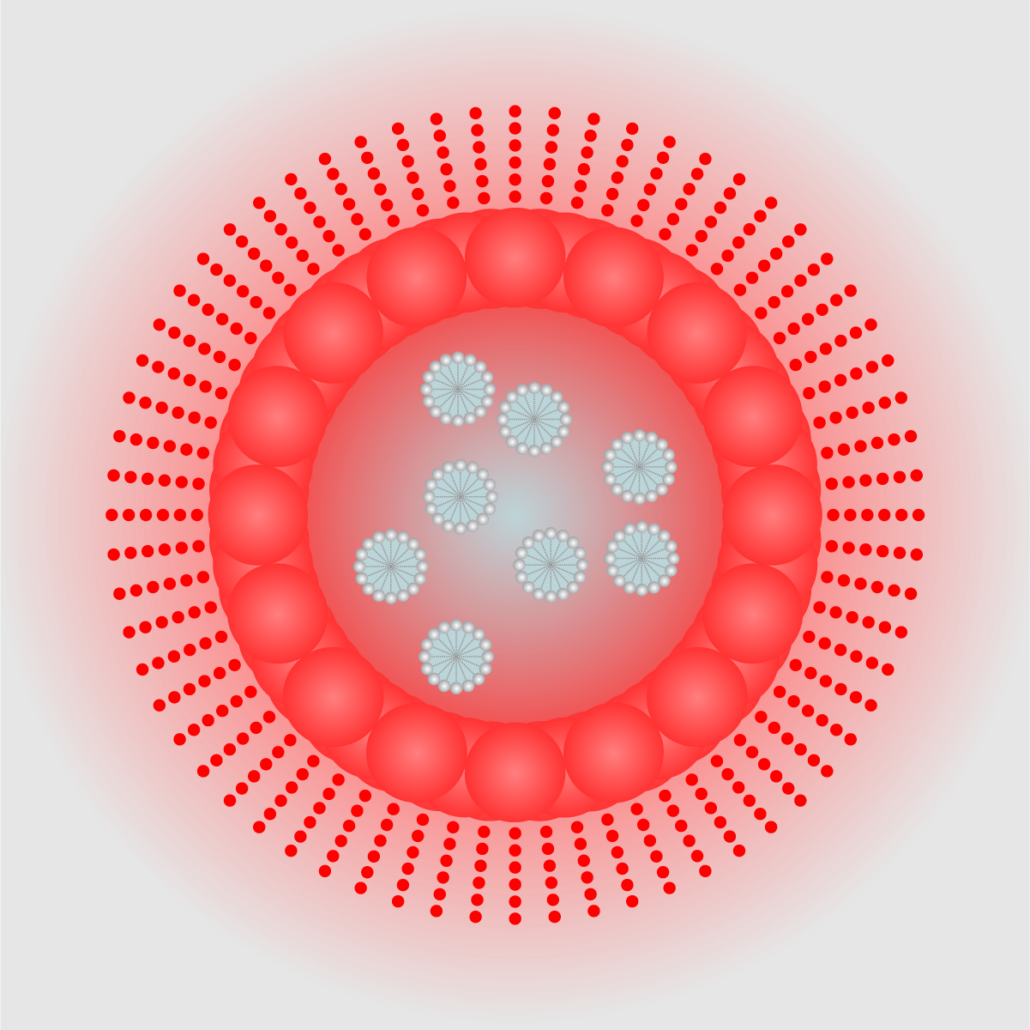

FIG. 1

Spherical Micelles immediately encapsulate liquid and vapor phased fuels within the micelle, effectively placing them in a “chemical cocoon”.

FIG. 2

Stable long-term encapsulation is accomplished as fuel is successfully separated from oxygen on a molecular level.

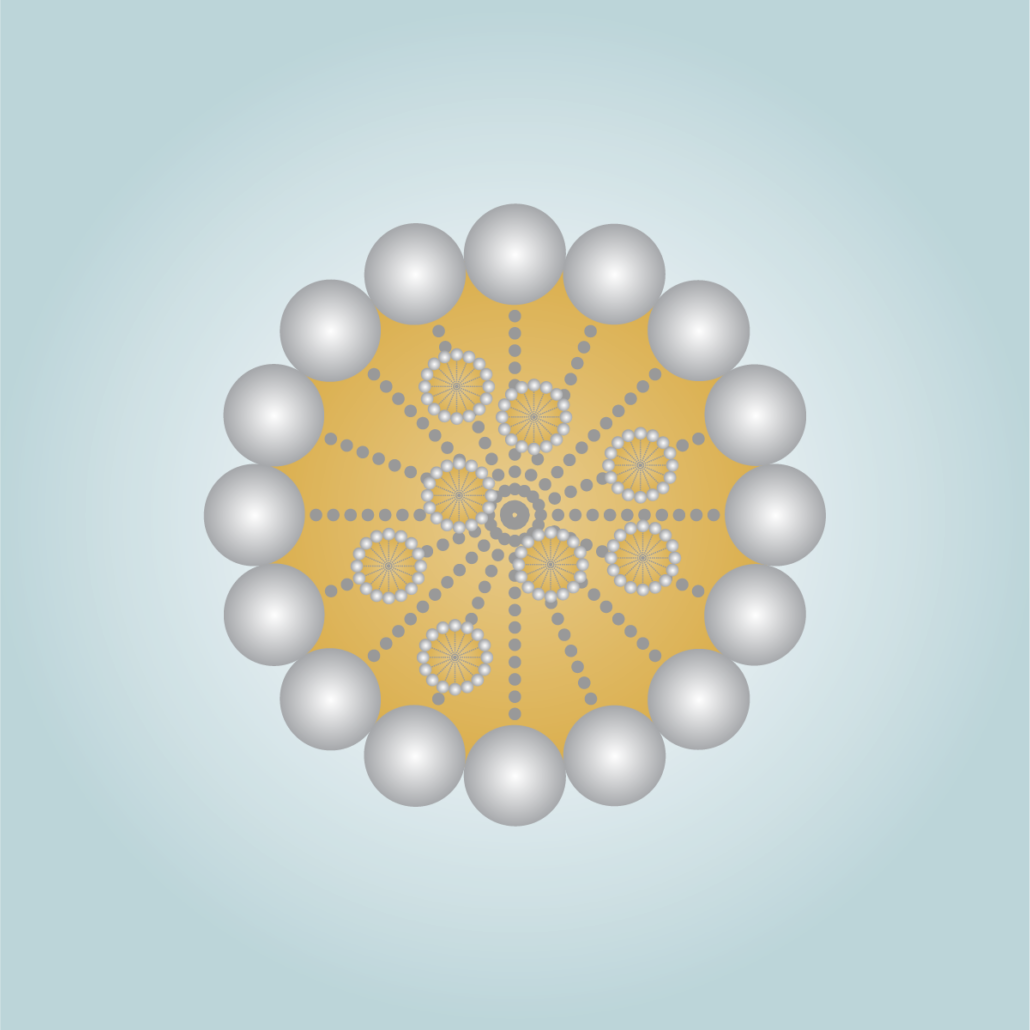

Rapid Heat Reduction

BENEFITS

- Improved Knockdown Capabilities

- Effective Droplet Utilization

- Prevent Scalding Steam / Excess Runoff

- Save Time / Resources / Energy

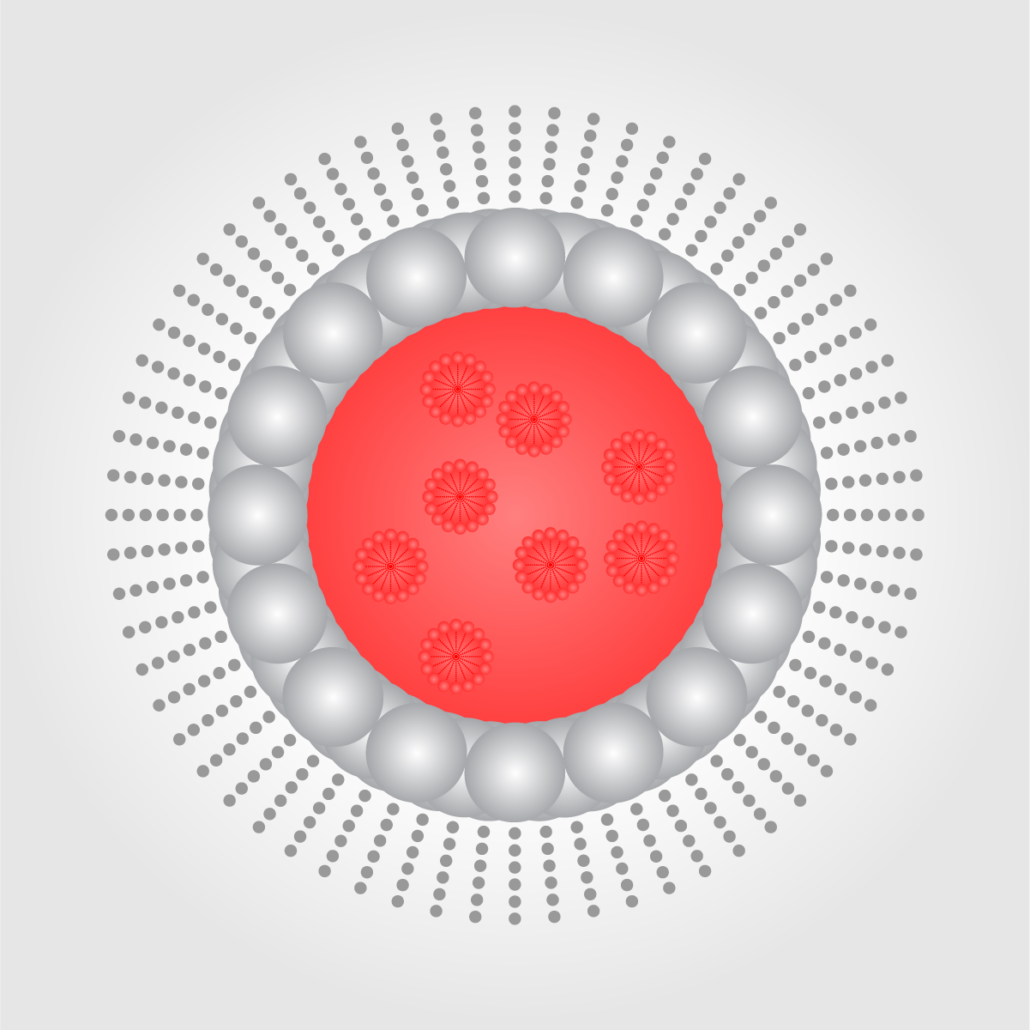

FIG. 1

An Encapsulator Agent droplet’s “skin” acts as a heat sink, rapidly driving thermal energy inward without generating scalding steam.

FIG. 2

The entire droplet is utilized to penetrate hot spots during this process of thermal conveyance, leaving minimal runoff.

Free Radical Interruption

BENEFITS

- Reduced Carcinogenic Toxin Concentration

- Improved Safety / Health / Longevity

- Improved Visibility / Air Quality

- Reduced Environmental Impact

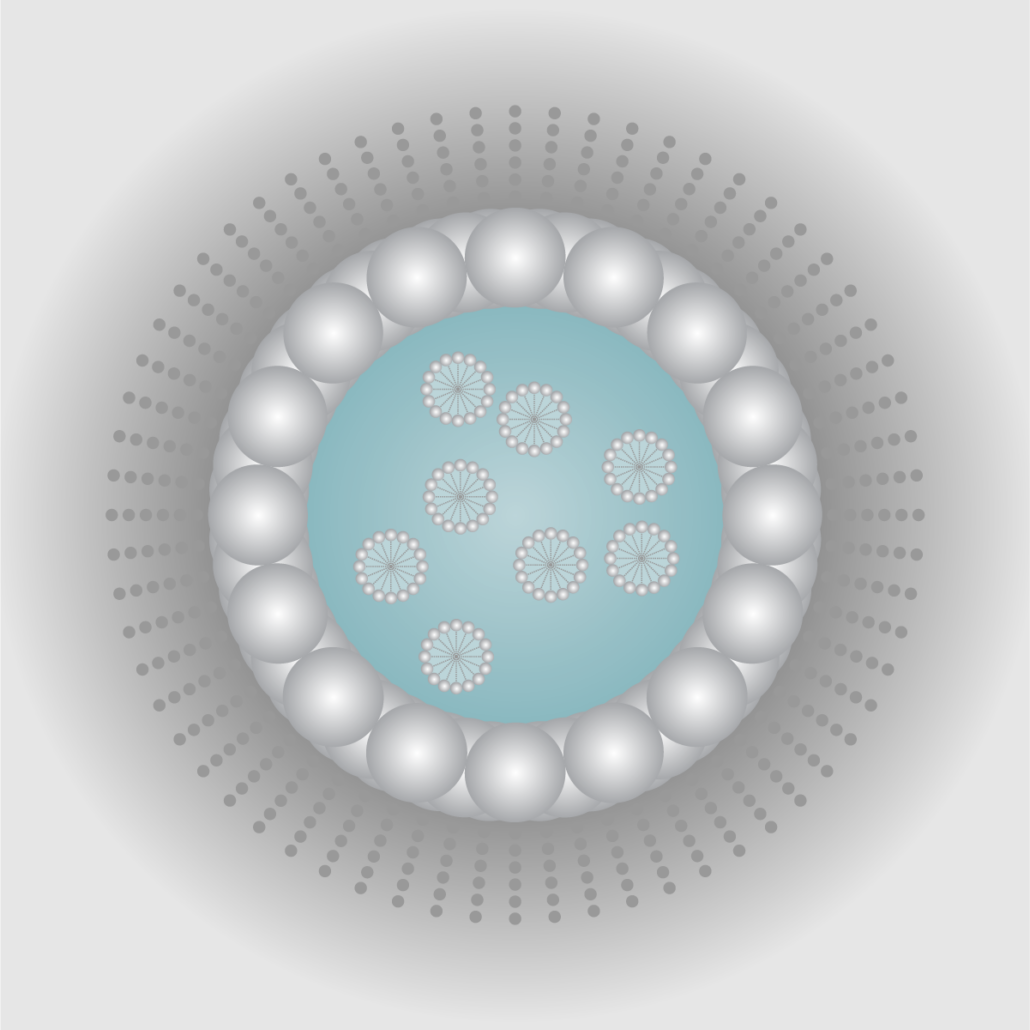

FIG. 1

An Encapsulator Agent droplet’s high molecular weight creates a barrier, stopping the chemical reaction and ceasing smoke and soot production.

FIG. 2

Non-polar tails absorb carbons and hydrocarbons present in smoke and soot, drastically reducing toxin concentration at the nozzle.

Contact

Please fill out the form below for more information or to request a quote!