Advanced Fire Protection with Fluorine-Free Foam

When it comes to fire protection, over-engineered systems can hinder incident response.

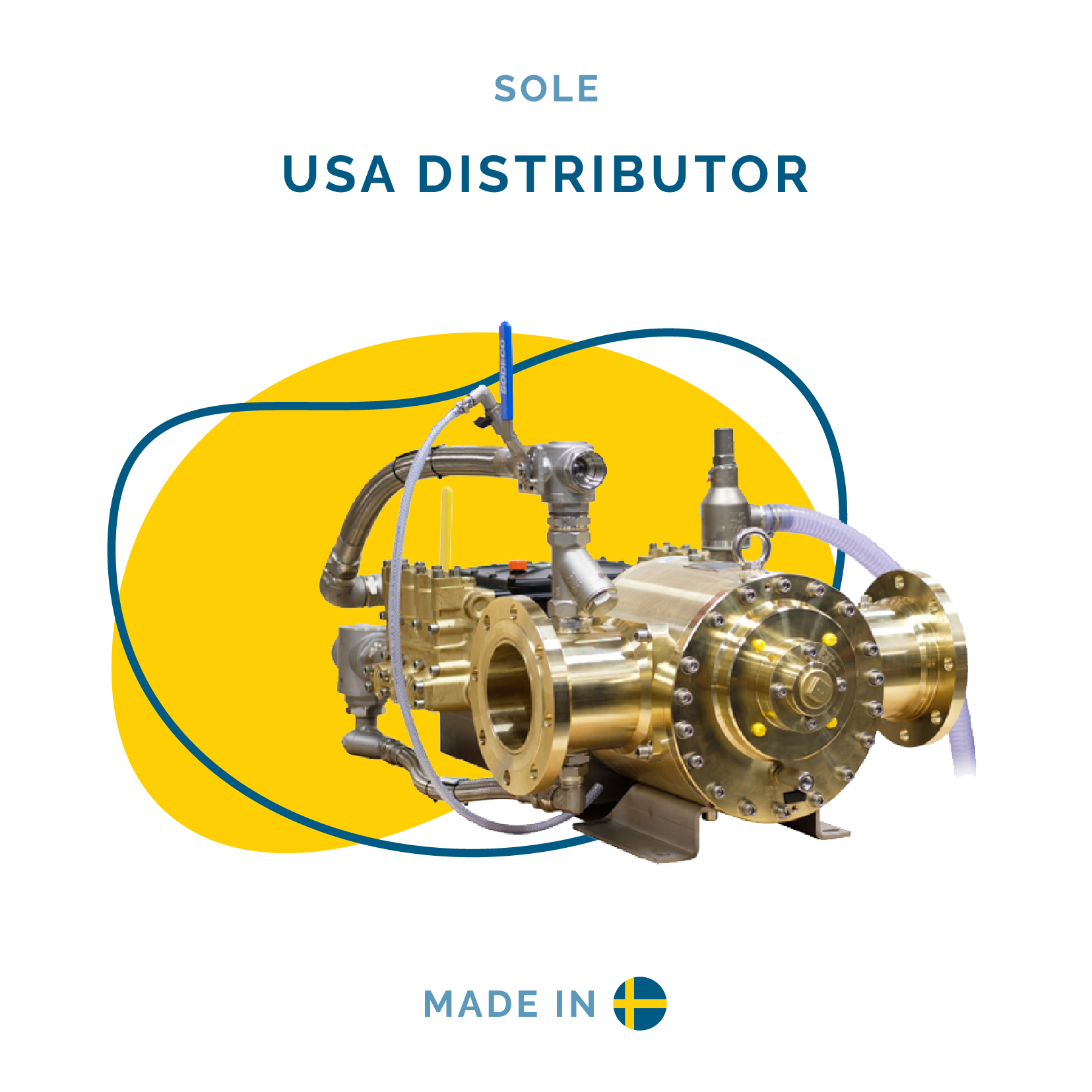

Firemiks offers simplified solutions and excellent protection against today’s fast-growing fire hazards. These water-driven proportioner systems are designed to work with AFFF foams, AR-AFFF, and Fluorine Free Foam (F3), offering an environmentally responsible choice for extinguishing class A and class B fires. Firefighting foam works by forming a foam blanket over the fuel to extinguish the fire and prevent re-ignition of the vapors.

There’s an increasing shift from AFFF foam systems to SFFF (synthetic fluorine-free foam) in the United States. Unlike traditional firefighting foams, F3 formulations are free from polyfluoroalkyl substances (PFAS). These substances can negatively impact human health and the environment. In January 2023, the Department of Defense released a military specification in response to the negative impacts of PFAS. This new specification said that firefighting foams used on military bases must be able to extinguish class B hydrocarbon fuel fires without the presence of PFAS.

This information details why Fluorine Free Foam (F3) systems may require a new design and a larger tank. Many non-fluorinated foams have a viscosity of 3,000-6,000 or more. This is the perfect time to convert your bladder tank to a modern, reliable, and economical water-driven proportioner system.

Where is Firemiks Used?

This fluorine-free product is a mechanical dosing system mainly used by fire departments in the oil and gas industry. It’s used when there’s a need to protect highly flammable materials with class B foam or other additives, such as tank farms, petrochemical plants, harbor jetties, pump rooms, warehouses, and more. Its water-driven design allows it to function without external energy, making it ideal for use in sprinkler systems and fire trucks.

The Science Behind F3 Foam

NFPA RF Report 165 UL Fire Tests

A Fluorine-Free Foam Product Requires Higher Application Rates Than AR-AFFF (Alcohol Resistant Aqueous Film Forming Foam).

IPA FIRES

Requires 2-4x more Fluorine Free Foam (F3) than AR-AFFF.

F3 MILSPEC GASOLINE

Requires 3-4x more Fluorine Free Foam (F3) than AR-AFFF but shorter burnback resistance.

E10 GASOLINE

Requires 6-7x more Fluorine Free Foam (F3) than AR-AFFF.

| UNIT # | MIN FLOW | MAX FLOW | INLET |

|---|---|---|---|

| FM-00180 | 13 GPM (49 LPM) | 48 GPM (180 LPM) | 1.50″ |

| FM-00450 | 20 GPM (76 LPM) | 119 GPM (450 LPM) | 2.00″ |

| FM-00800 | 36 GPM (136 LPM) | 212 GPM (800 LPM) | 2.50″ |

| FM-01200 | 69 GPM (261 LPM) | 317 GPM (1,200 LPM) | 3.00″ |

| FM-01800 | 69 GPM (261 LPM) | 475 GPM (1,800 LPM) | 4.00″ |

| FM-02400 | 83 GPM (314 LPM) | 634 GPM (2,400 LPM) | 4.00″ |

| FM-03200 | 92 GPM (348 LPM) | 846 GPM (3,200 LPM) | 6.00″ |

| FM-04500 | 132 GPM (500 LPM) | 1,190 GPM (4,500 LPM) | 6.00″ |

| FM-06000 | 158 GPM (598 LPM) | 1,587 GPM (6,000 LPM) | 6.00″ |

| FM-08000 | 211 GPM (799 LPM) | 2,116 GPM (8,000 LPM) | 8.00″ |

| FM-10000 | 211 GPM (799 LPM) | 2,645 GPM (10,000 LPM) | 10.00″ |

How Does Firemiks Compare?

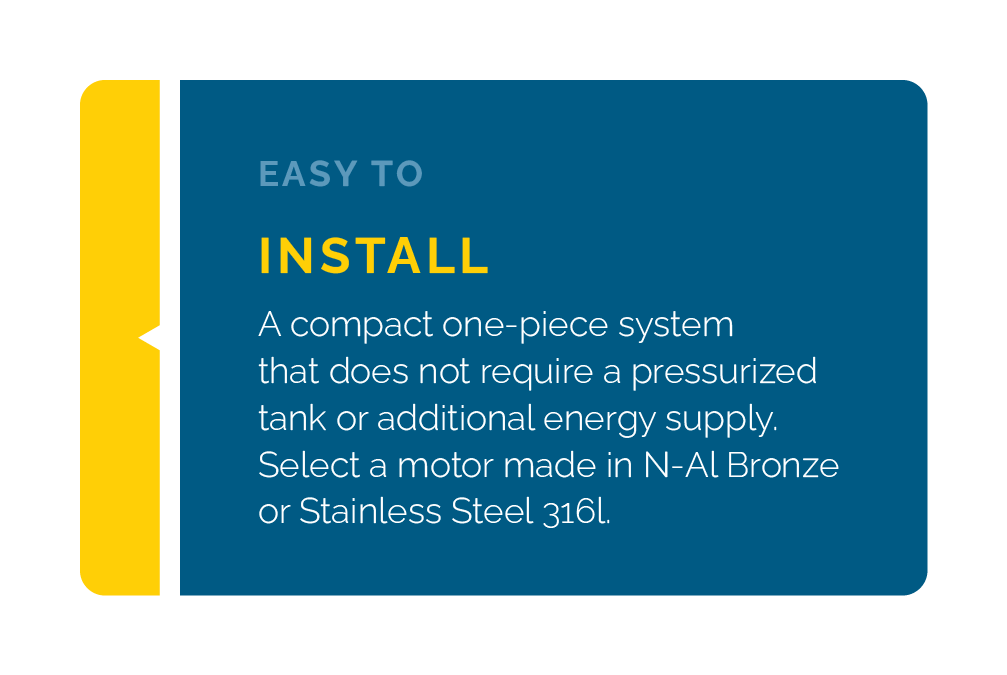

Firemiks sets the standard with its firefighting foam products. They are 1) Easy to Install, 2) Easy to Use, and 3) Easy to Test. Its compact, one-piece design ensures a hassle-free setup without the need for a pressurized tank or external power source, making it ideal for various applications. In operation, this fluorinated foam system eliminates the need for complex pressure balancing and allows for a wide range of flow rates and dosing options. It’s an eco-friendly and cost-effective solution that delivers excellent performance and reliable fire extinguishment.

Maintenance

Maintenance is straightforward and there’s no lubrication required. Simply crank the shaft every six months and safely refill your tank with ease as needed. For NFPA 25 testing, pull samples directly from your tank.

Proportioning

Proportioning is automatic and accurate, even in the event of a power failure. Outages are not uncommon during a larger industrial fire. Consistent dosage rates will offer your team peace of mind when it matters most.

Impact

Prioritize the health and safety of your personnel. Avoid unplanned discharges, contamination, and unexpected disposal costs with a system that works hand-in-hand with Fluorine Free Foam (F3).

Brochures

Contact

Ready to take the next step in your fire suppression capabilities? Explore this innovative fluorine-free firefighting foam and request a quote today to ensure the utmost safety and protection of your equipment and assets.